EMC Vehicle Testing Facilities

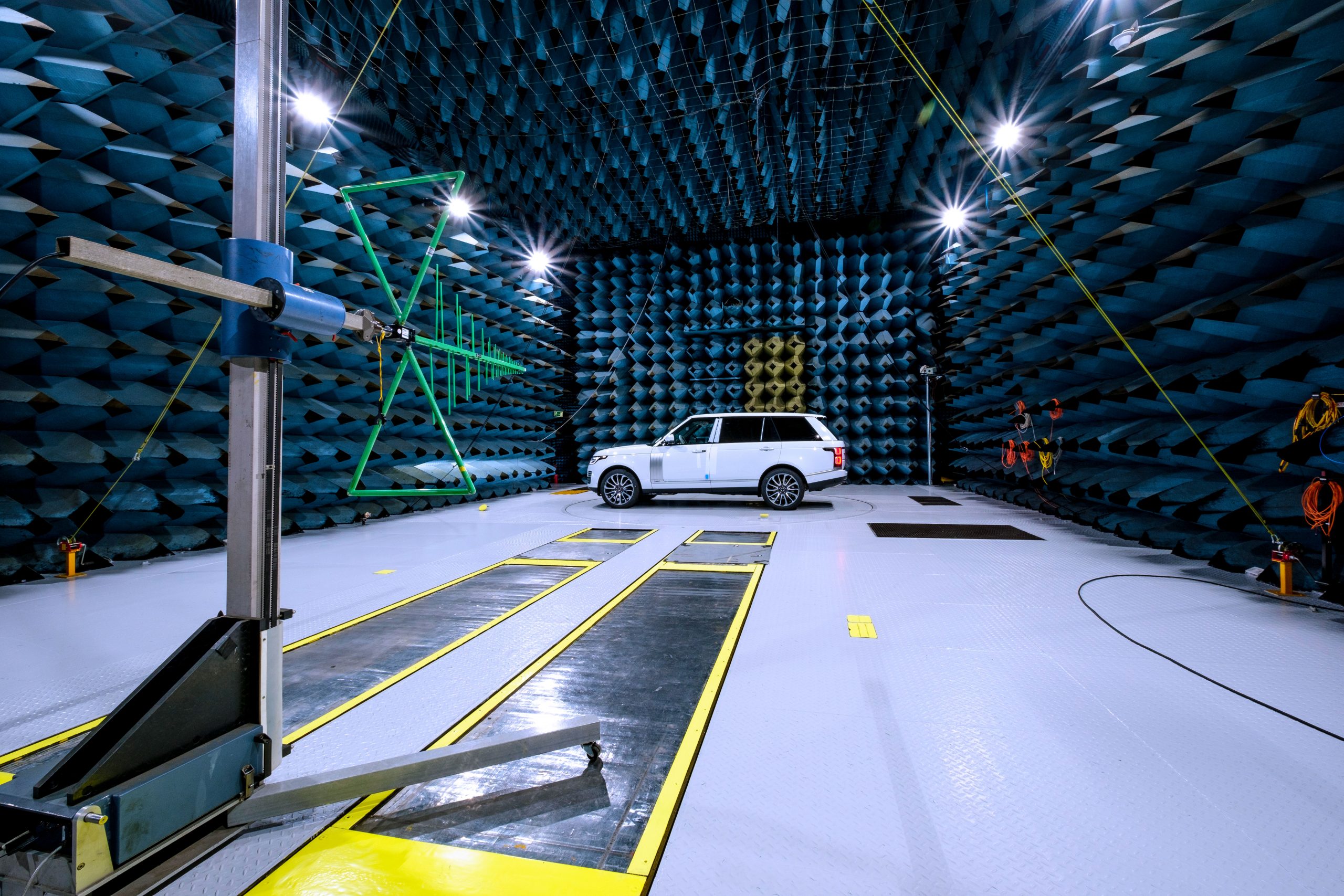

Our vehicle and platform Electromagnetic Compatibility (EMC) facilities are accredited for all applicable automotive, off-highway, military & commercial EMC international standards and directives as well as being approved and recognised by all major vehicle manufacturers test schedules.

Our facilities meet the requirements of the automotive UNECE Regulations, where we are also an EMC Technical Service for the VCA, RDW, NSAI & VSCC enabling our customers the swiftest route to compliance.

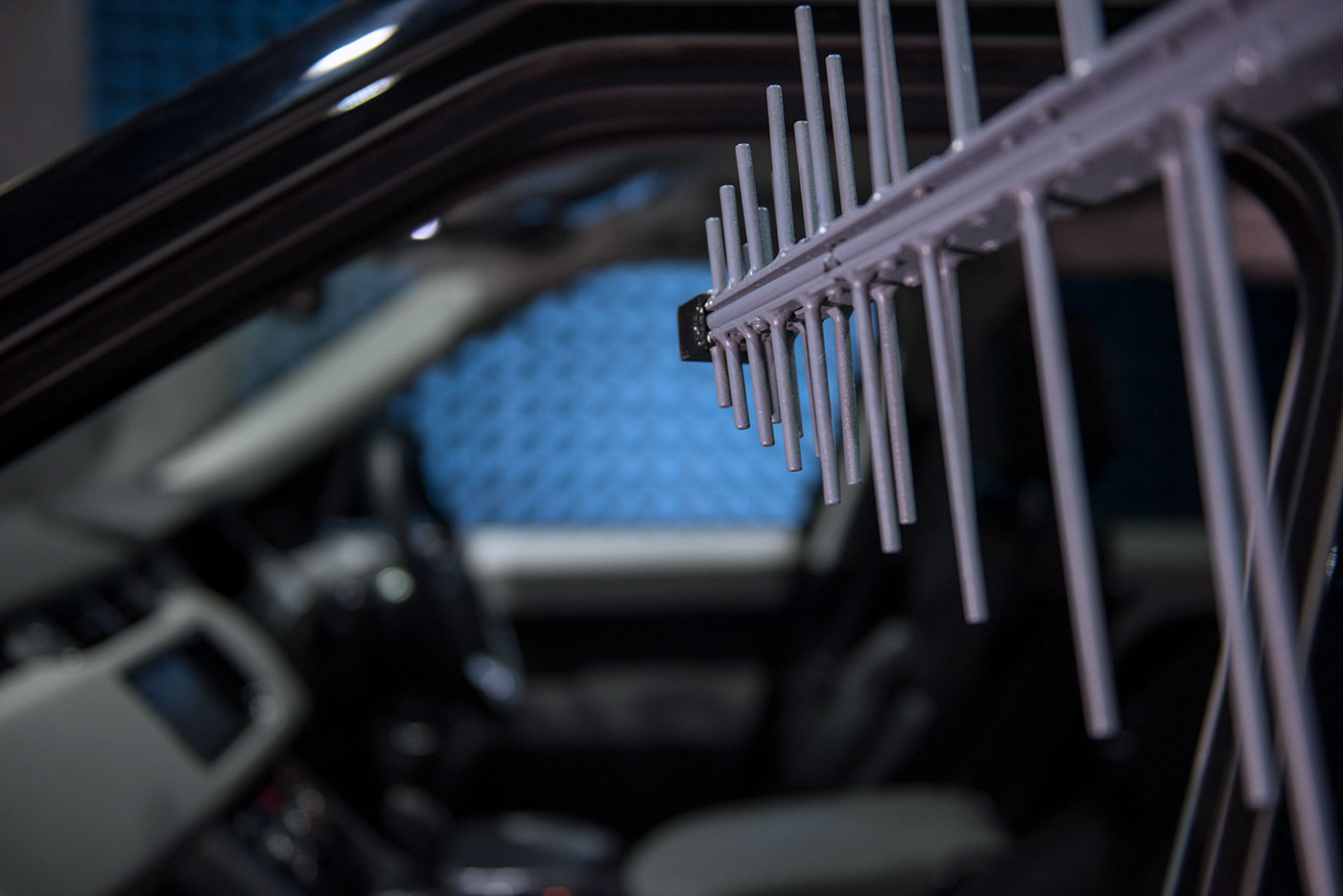

HORIBA MIRA’s expertise and capabilities in EMC encompass RF Immunity & Emissions, Electrical Transients, Power Quality, Polar Analysis and EMF testing.

Our vehicle test facilities support dynamic test scenarios with the use of our 4-wheel, independent axle dynamometer, accommodating the largest bus and truck configurations. Additionally, and with a static floor loading capacity of 100 tonnes, the largest military and off-highway products may be accommodated.

Infotainment system performance, radio reception assessments and polar analysis of the vehicles onboard antennas is achieved through the use of the facility’s turntable and bespoke test software.

Furthermore, our Electrical Workshops have the equipment to support the Power Quality test requirements of UK Defence Standard 61-5.

Our facilities include:

- 24 hours per day operation to reduce dependence on prototype

- 2 ALSE Vehicle & Platform EMC Facilities

- 4 Electrical Workshops

- Electric Vehicle (xEV) & Sub-Component Facility

- Radiated & Conducted Emissions

- Radiated Conducted Immunity

- Electrical Transients

- Electromagnetic Fields

- Fibre optic monitoring for all automotive networks (CAN, LIN etc) pneumatic control of vehicle systems and remote access for diagnostic support from anywhere in the world

- Broadcast suite enabling Radio, TV, Cellular and E-Call etc simulations

- Re-radiating GNSS, 3G and 4G networks

- Turntable and variable wheelbase twin-axle dynamometer capable of 120kph